107/1 ถ.เฉลิมพระเกียรติ ร.9 แขวงประเวศ เขตประเวศ กรุงเทพฯ 10250

Tel : 02-726-8000

Fax : 02-726-8266

Email : sales@pneumax.co.th

Vacuum Pump

Screws Type Vacuum Pump : Leybold

ปั๊มสุญญากาศ Oil less : Screws Type Vacuum Pumps เทคโนโลยีใหม่ที่ง่ายต่อการใช้งาน ไร้เสียงรบกวนในสายการผลิต ไม่ต้องใช้สารหล่อลื่น

Vacuum Pump (ปั๊มสุญญากาศ) : Leybold

ตัวแทนจำหน่ายปั๊มสุญญากาศ แวคคัมปั๊ม Leybold Vacuum Pump, Oil Diffusion, Turbomolecular, Refrigerator, Sogevac, Trivac, Screw Vacuum, Rotary Vane, Screw Line Dry, Oil Free Scroll, Rotary Piston Pumps

Vacuum Pump

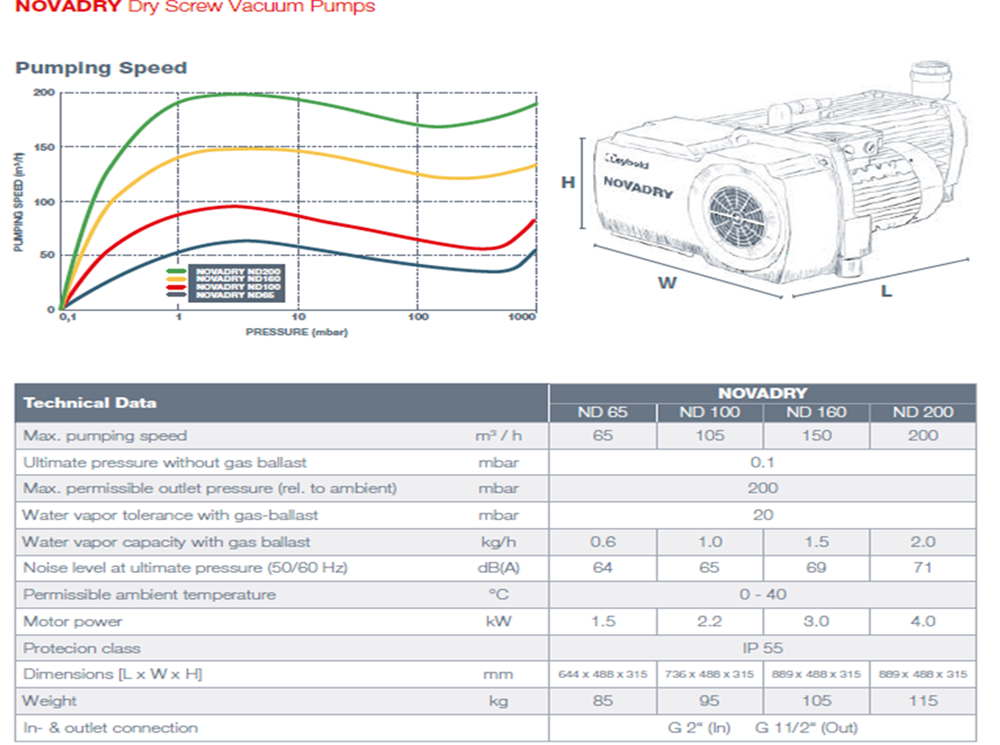

Specification :

Application :

แผนก Vacuum Pump

Email : sales.pum@pneumax.co.th

โทรศัพท์ : 02-726-8000 ต่อ 610 - 621

ติดต่อสอบถาม

107/1 ถ.เฉลิมพระเกียรติ ร.9 แขวงประเวศ เขตประเวศ กรุงเทพฯ 10250

Tel : 02-726-8000

Fax : 02-726-8266

Email : sales@pneumax.co.th

To reset your password, enter the email address you use to sign in to form